How a cannon is made

The very earliest cannon made in England in the 14th Century were cast in bronze. Bronze is an alloy of copper and tin with a melting point of about 950°C (1742°F). Unlike cast iron, it has some elasticity that makes it perfect for containing the force of the explosive power.

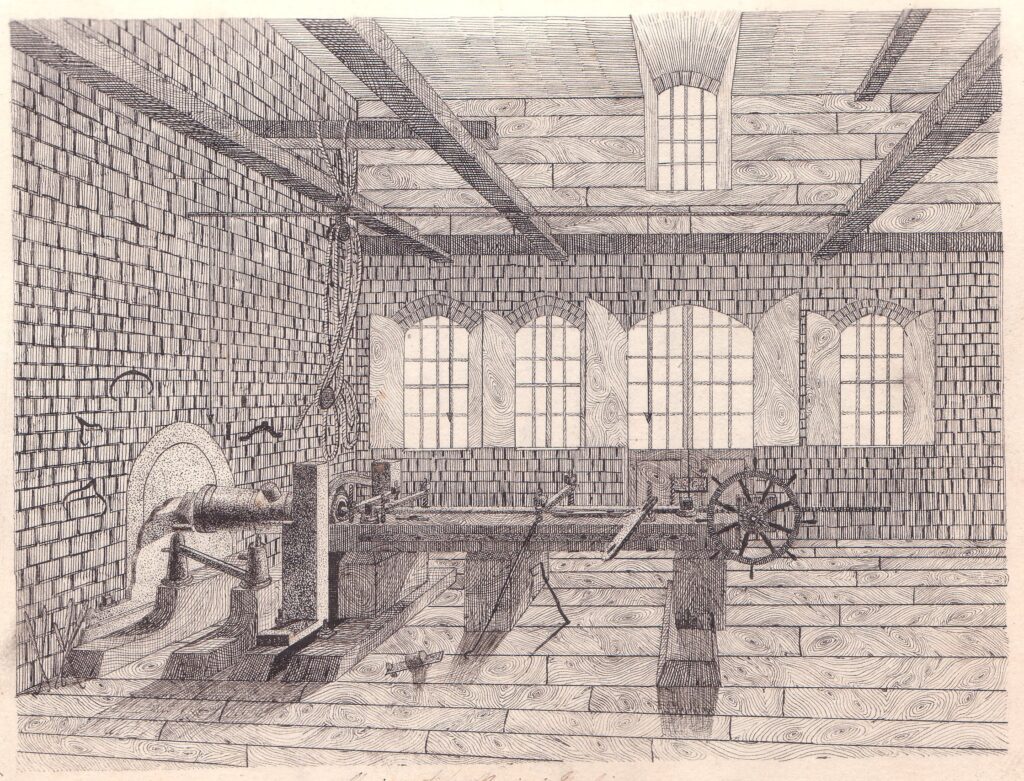

To start, a pattern is made of wood and other materials in the shape of the cannon and that is used to make a mould. Molten metal is poured into the mould to produce the barrel. It is then bored, smoothed and engraved to produce the final gun.

The history of cannon casting in England provides an insight into the skills used to produce guns that have won battles worldwide. The research we have conducted over the last 25 years allows us to exploit that knowledge and, together with modern technical understanding, produce cannon of beautiful traditional excellence.